WhatsApp)

WhatsApp)

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

cement raw material grinding cement raw material grinding,raw milling cement,unityitin Cement GrindingVRM or Ball,_ Whilst it .

Raw Material Grinding. The desired raw mix of crushed raw material and the additional components required for the type of cement, silica sand and iron ore, is ...

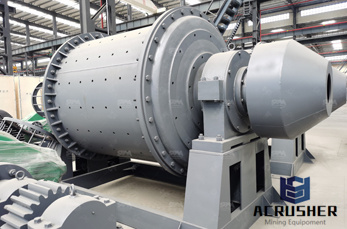

wet grinding and dry grinding both open circuit grinding CGM grinding plant. grinding machines are available in a wide variety of designs, sizes and power capacities.

Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover ... Now cement plant grind the raw .

Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and ...

How we make cement Titan raw material grinding cement,The raw materials for cement production are mined by the use of explosives (drilling blasting) or by ...

Raw material grinding is one of the processes used to manufacture cement of highest quality.

Aug 19, 2017· Feed Back. Learning text part 05 Mortar. Brick and block production Learning text part 05 Contents page Introduction 1 History of brick making 1 Clay ...

Cement Grinding Mill It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement ...

Cement grinding Vertical roller mills versus ball mills. 3 These differences between cement grinding and grinding of raw materials made it a serious challenge to ...

The cementmaking process, from crushing and grinding of raw materials, through roasting of the ground and mixed ingredients, to final cooling and storing of the ...

Raw material preparation aims to ... The production of one ton of portland cement requires more than ton of raw ... If raw material grinding is ...

Raw Materials for Cement Manufacture. Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a .

grinding of raw materials in cement industry. Raw Mill Building IN CEMENT INDUSTRY CGM Grinding Plant . Ball grinding mill, roller grinding mill for .

Mathematical Problems in Engineering is a peerreviewed, ... The second stage and third stage are to burn the raw material and grind cement clinkers respectively.

The raw material preparation stage of cement manufacture results in the production of a rawmix that is in ... These were used for dry grinding of dry raw materials, ...

Know More ... raw material grinding cement makabsworg Cement Kilns: Raw Material Preparation raw material grinding cement,So, for example, in .

CEMENT RAW MATERIALS PLANT SIZES. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The x .

Industry News. cement industry materials. portland cement raw material; raw material grinding cement motar; raw material cement .

Industry News. Optimum grinding of raw materials, cement and coal. This innovation enables large cement producing facilities to be designed with the onemillconcept ...

Raw material grinding in a cement plant, Grinding Mill China Raw material grinding is a critical mechanical .

Virtual Cement Plant Tour Portland Cement Association (PCA) bulk by trucks, rail, or barge. From the grinding mills, the. cement is conveyed to silos where. it awaits ...

3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement .

WhatsApp)

WhatsApp)