WhatsApp)

WhatsApp)

wet grinding and dry grinding; both open circuit . CGM grinding plant. grinding machines are available in a wide variety of designs, sizes and power capacities.

Corn wet milling and dry milling are the predominant methods of processing corn and each method produces distinct coproducts. Read more here.

Wet milling is robust, relatively easy to implement and offers a range of benefits over dry milling for pharmaceutical, food beverage, personal care and ...

Ball mill, Ball millingcutter All industrial, ball mill / horizontal / for the pharmaceutical industry / wet 90 M HOSOKAWA, Dry grinding as low as below 5µm ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction needs.

Corn Milling, Processing and Generation of Coproducts Corn, ... There are two distinct processes for processing corn, wetmilling and drymilling

Thread milling. Choice of tools; ... Dry or wet machining Dry machining is always recommended as cutting fluid emphasizes temperature variations at entry and exit, ...

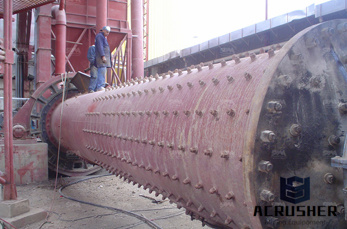

Industry News. wet dry ball mill for limestone. Home Raymond Mill Vertical Roller Mill MTM Trapezium Grinder Ball Mill About Us Contact Us Live Chat wet dry ball mill ...

Materials, such as ores, chemical substances, ceramic raw materials, magnetic coatings and paints, can be milled using a dry milling or wet milling process.

Sep 18, 2013· Wet milling, sometimes referred to as malt conditioning, is something I have read about plenty but never actually tried. Most of the homebrewing literature ...

Picking, Wet Milling and Sun Drying ... Picking, Wet Milling and Sun Drying; Dry Mill and Sorting; ... Coffee in the fermentation tank at the wet mill.

About dry milling and wet millingrelated information:traditionally, ethanol from corn has primarily been produced through dry and wet milli... Chat Now!

Milling ByProducts of Cereal Grains. ... The main types of milling are dry and wet milling. Dry milling removes the outer fibrous materials from the seed.

Roland DGA recently announced the release of the DWX4W, our company''s first wetmilling machine. It was added to the Roland family of dental milling devices in ...

Wet milling: Wet milling with IKA''s inline machines is a safe and efficient alternative to dry grinding. Dry grinding creates a lot of dust which causes the need for ...

The Ethanol Production Process Wet Milling. While the basic steps remain the same, the process has been considerably refined in recent years, leading to a very ...

Dry or Wet Machining? ... In this case, a coolant supply may be destructive due to critical thermal stress. In contrast, when dry rough milling, ...

Chris Frye of Whip Mix takes a look at the differences between wet milling and dry milling.

Compared to dry fractionation. The dry fractionation system ead of Germ Wet Milling can be simplified to reduce cost and maintenance; Highvalue, foodgrade market ...

Grain sorghum flours and grits will be evaluated for wet milling quality with an established benchscale procedure starting with 100g of material.

Influence of dry and wet grinding conditions on, It is well established in conventional ball mill grinding that the shape of the product size, Furthermore, the ...

Traditionally, ethanol from corn has primarily been produced through dry and wetmilling processes. The majority of ethanol production is from drygrind technology.

Leading expertise in dry grinding and wet milling applications in the pharmaceutical, food, chemical and personal care cosmetics industries.

Dry and Wet Milling Two different approaches in grain processing. As only the starch is needed as a carbohydrate source for the biological conversion process, the ...

WhatsApp)

WhatsApp)