WhatsApp)

WhatsApp)

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is: 2 2 3 1 bo Kd. (5) So, we have got the following: the optimal ball diameter d

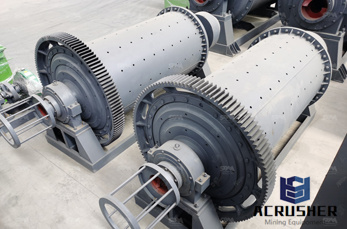

"Mining equipment used in drilling, crushing or grinding of various minerals are put to the test and may require more than one rehabilitation before being turned ... What is a Ball Mill? A ball mill is a type of grinding mill, purposed ...

Ball Mills : United Nuclear, Scientific Equipment Supplies Basic Information Operation: Ball Mills are a very efficient tool for grinding many materials into a fine powder. To use the Mill, the material to be ground is ... Chat Online

Basics in Minerals Processing Technical data: Spherical roller bearing supported ball mills . Screen types ... The ambition with this handbook, Basics in Minerals Processing, is not to give a. Live Chat wet screening in stage ...

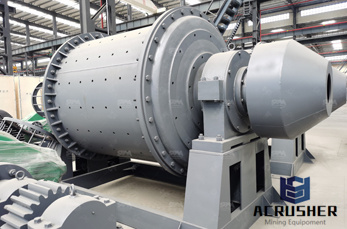

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate in either open or closed circuit and with or ...

Ball Mills : United Nuclear, Scientific Equipment . Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the ...

Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and ... » Learn More Mill (grinding ...

vikas puri new delhi cement grinding . Gurdwara C Block, Vikas Puri, New Delhi, ... new type high efficiency grinder raymond mill; cone type ball mill runing view; gold mining filter testing equipment; Get Price Online

The Explosion of a Ball Milling Jar The sound of the other shoe (1997) By Lloyd E. Sponenburgh ver since I wrote the original articles on how to build a ball mill (AFN November 1995), I wondered how destructive an event it would be if ...

Grinding media Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill. Grinding media sorting is performed when the ball load wears out. New ...

Ball mill machine is one kind of ore processing equipment, which is mainly used for single stage fine grinding and acts as second stage .

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input. ... RETSCH ball mills are available as mixer mills as well as planetary ball mills. ...

Tenova Bateman Mills (SAG, AG, Rod, Ball) Patterson manufactures a complete line of ball mills for every wet or dry grinding process for size reduction, and for dispersion and deflocculation in solidtiqu.. STEEL BALL MILLS ...

Name of the component : Ball mill Quantity required : One EMD Amount :,000/ Cost of the Tender Document : Rs. 150 Delivery : .

Laboratory roll mill machine is a kind of sample pulverizing machine, which can grind coarse particles into micro powders. It can mill the materials from 10mm maximum into 15um minimum powder. This machine can deal to 10L ...

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

めまれている· At some point in this pyroart adventure, we start to hear or get the feeling, that we need a ball mill to grind chemicals very fine or to make highquality black powder. This project will not attempt to be a comprehensive review of ball ...

Our company produces raymond mill, high pressure grinding mill and other milling equipment, as well as ball mill, rod mill, cement mill and other grinder mills special for mining industry and building materials industry.

How to Use a Ball Mill Safely and Effectively I have some lump charcoal that just came out of my retort after I cooked it, and I want to turn it into airfloat charcoal. Or, the directions say to ball mill my rocket fuel for an hour. An article ...

SUMITOMO KAGAKU 2007II 3 Design Method of Ball Mill by Discrete Element Method The spring coefficient in the tangential direction Ks can be obtained based on the defining equation for the Lame constant shown in (Eq. 8 ...

Dave, Just a note of thanks for the job the crew did over the past week on our lime slaker and ore ball mill. Once again Kaltech has come through for us. Shawn and boys did well and hit their marks when needed. I missed them ...

This machine is a kind of ball mill which is suitable for small batch production, It owns high efficiency, low noise and functional features, and it can mill the materials from 3~10mm maximum into ~1µm minimum powder.

Slag ball mill is a kind of equipment used to grind the slag into powder particles. The technical that uses the tube mill on the production of slag has been very mature.

WhatsApp)

WhatsApp)