WhatsApp)

WhatsApp)

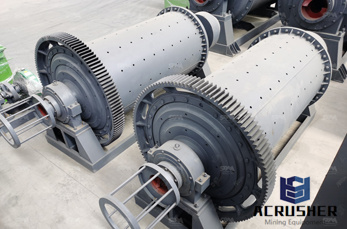

Traditional methods, the ball mill during the processing of materials usually can play two effects, one is broken effect, one is the grinding effect.

SAG Mill Process Control What do you prefer? Controlling Weight (within a range) by manipulating mill speed and keeping a constant feed rate? Controlling weight by ...

Grinding and Milling Systems Course. ... This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process.

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill ...

A cement mill (or finish mill in ... The recent history of the technology has been mainly concerned with reducing the energy consumption of the grinding process ...

The roller mill is by far the most important grinding machine in a mill. Whether processing maize, wheat, durum wheat, rye, barley, or malt – offers the ...

Fast, efficient, laboratory grinding mills from Union Process offer reliable flexibility, repeatability low maintenance, with full scaleup capability.

GRINDING MACHINES Grinding is the process of removing metal by the application ... convenient for grinding the faces of formrelieved milling cutters and broaches.

Mica crushing machine and grinding mill used for beneficiation process plant. Mica mining equipments manufacturer in India, Russia, USA, China, Brazil.

Ore processing is a 24 hour operation. ... except it has a larger proportion of steel balls to assist in the grinding process. Following grinding in the ball mill, ...

Sep 16, 2013· Video embedded· Grinding process for ball mill, a simulation with by 3ds max 2012, this is an air swept mill with m dia. used in Polysiuos factories (German design).

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

milling and grinding process handbook pdf . Ceramic Industry – Union Process – New Brochure. The brochure also details other features of the DMQMill line ...

Advanced process control for grinding circuits Unlock the unknown potential of your mill White paper, June 2015 Recent copper price evolution pushes

INTRODUCTION. Grinding is the second step of mineral processing and the last stage of the comminution process. The product from a crushing unit is fed to a mill in ...

CEMENT GRINDING OPTIMISATION ... dry grinding, process optimisation, ... There are efficiency factors for dry grinding, open circuit ball milling, ...

Outotec HIGmill® high intensity grinding mill. ... Optimizes online particle size to maximize downstream process efficiency; Gives you a compact and simple ...

Grinding (abrasive cutting) – Wikipedia, the free encyclopedia. Electrolytic inprocess dressing (ELID) grinding is one of the most accurate grinding .

Grinding mill selection. An Amkco grinding mill is selected in case of special inorganic material. Such mill is efficient down to submicron and is converting the ...

Define milling. milling synonyms, milling pronunciation, milling translation, English dictionary definition of milling. n. 1. The act or process of grinding ...

Lab Grinding Mills In a laboratory setting, most materials used for sampling are nonhomogeneous mixtures. The best method of obtaining a small sample of these ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

Union Process manufactures a broad line of standardsetting wet and dry grinding Attritors and small media mills, and offers a wide assortment of grinding media

WhatsApp)

WhatsApp)