WhatsApp)

WhatsApp)

INDUSTRY SOLUTIONS COAL PREPARATION DENSE MEDIUM WASHING PLANT The dense medium washing plant is the most efficient separation process available. It is ideally suited for: • SEPARATION OF DIFFICULT COAL ...

Coal processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations Products: Modular Coal Preparation Plant (MCPP) comprising of vibratory screening equipment, fine ...

CR4 Thread: High Magnetite Consumption The Coal Washing Process a typical Dense Medium Cyclone Plant ... Magnetic Separators that recover the magnetite and ... coal washing process CGM mining application fine sand ...

3 1. INTRODUCTION The concept of fine coal beneficiation by dense medium is neither new nor untried. The first plant that employed dense medium to beneficiate fine coal was built at Tertre in Belgium in 1957. Approximately nine ...

Performance Optimisation of Fine Coal Washing Circuits Introduction Coal washery circuit and equipment design in South Africa have not changed significantly over several decades. Due to its high middlings content, South

July 17, 1956 Filed March 2, 1954 FIG. I c. KRIJGSMAN ET AL 2,754,963 COAL WASHING PROCESS 2 SheetsSheet l July 17, 1956, V c, KRUGSMAN ET AL 2,754,963 com. WASHING PROCESS Filed March 2, 1954 k 2 ...

2008/07/25· Gravity concentration of hard lignites using conventional jigs and heavy media separation equipment is prone to produce coalrich fine tailings. This study aims to establish a fine coal recovery process of very high ...

What Is Coal Preparation? • Coal preparation is the removal of undesirable material from the RunofMine (ROM) coal by employing separation processes which are able to differentiate between the physical and surface properties of ...

4 Thermal Drying Cost Summary 65 4 South African Practice 66 Fine Coal Treatment ...

pose Of the plant: Coal preparation fall general types : (1) conducted in water—only rredium, and (2) ti¥)se ænducted in a mixture of water and a high— gravity material such as nngnetite (dense nedium sys— ) . The generalOf 1(1) ...

Fine Cleaning coal output. 1,coal washing maching, sorting high precision,coal washer, separation efficiency is 95%. 2, Single less electricity, coal process machine... » Learn More Coal preparation plant Wikipedia, the free » ...

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks ...

TECHNOLOGIES F0R FINE COAL BENEFICIATION IN INDIA Dr. Deputy Director Head, Coal Preparation Division Central Institute of Mining Fuel Research ... INTRODUCTION 9Indian coals, in general are inferior in ...

The dense medium washing plant is the most efficient separation process available. It is ideally suited for • Difficult coal separation • Cleaning high value coal for domestic and industrial use. The overall process differs from the natural ...

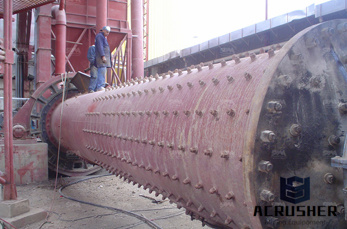

coal washing process coal washing process XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly ...

The major emission source in the fine or coarse coal processing phases is the air exhaust from the air separation processes (air tables). For the dry cleaning process, these emissions are generated when the coal is stratified by ...

types of coal washing process XSM is a leading global manufacturer of crushing and milling equipment (types of coal washing process),XSM also supply individual (types of coal washing process...) crushers and mills as well as spare ...

DOE Fossil Energy: Clean Coal Technology One way is to clean the coal before it arrives at the power plant. One of the ways this is done is by simply crushing the coal into small chunks and washing it. » Learn More coal washing ...

2008/07/22· This study aims to establish a fine coal recovery process of very high efficiency at reasonable capital investment and operational costs. The technical feasibility to upgrade the properties of the predeslimed fine refuse of a lignite ...

In this process coarse and fine coal is separated so to accommodate for specific markets and industrial usage. Screening takes place at a processing plant adjacent to Ewington Mine. Griffin Coal''s screened coal is ideal for ...

Parnaby Cyclones has been a key partner in maximising the efficiency of coal mining and developing coal washing plant for nearly 50 years. We have developed coal washing plant for separating different ...

An Efficient Process for Recovery of Fine Coal from Tailings of Coal Washing Plants T. Ç[idot]çek Faculty of Engineering, Department of Mining Engineering, Dokuz Eylül University, Buca, İzmir, Turkey, İ. Cöcen Faculty of, ...

Fine Coal Recovery from Tailings Impoundment''s. Process Requirements. The original process for the Wollondilly plant was designed for the recovery of + .125mm coal at <12% ash. This involved 1. Dredge reclaiming and slurry ...

The traditional separation technique of coking coal is, heavy dense medium cyclone processing, fine particle flotation, the mature separation technology based on coarse coal heavy dense medium process and ...

WhatsApp)

WhatsApp)