WhatsApp)

WhatsApp)

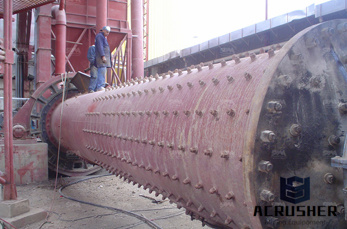

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

ρ charge = total coal mass + ball mass / J ∗ Mill volume. ... Y. KandaExperimental investigation on a grinding rate constant of solid materials by a ball mill ...

Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in ... The total volume of the balls, ...

Calculate Ball Mill Grinding Capacity. ... plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume ...

Aug 03, 2016· Video embedded· Contact Us: calculating of volume in ball mill capacity Description : grinding volume ...

volume of ball in ball mill – Grinding Mill China. volume of ball in ball mill. Random products: automatic brake shoe outer dia grinding machine manufacturers in ...

Hi All, I would like to know about ball mill calculation. Could you give me references? ... Mill dimensions → Bulk volume of the balls ball size : ...

Planetary Ball Mills ... – Planetary Ball Mill PM 100 5 ... nominal volume of 12 to 500 ml. It can grind up to 8 samples simultaneously

calculation of ball mill charge volume. How to Calculate Charge Volume in Ball or Rod MillMining andThe charge volume of a ball or rod mill is expressed as the ...

grinding media volume in ball mill. home grinding media volume in ball mill. Inquiry. If you have any questions, please tell us, Ball Mill Grinding Media, ...

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the ballto ... the particles occupy of the mill volume.

Shop huge inventory of Ball Grinding Mill, Ball Mill Media, ... ceramic balls and cylpebs are very hard wearing and ideal for ball milling. For volume calculations, ...

How Can i calculate the wear rate of grinding media in ball mills Cement Industry Experts. Discussion | by which the mass rate of consumption of a grinding

Ball Mill Loading Dry Milling. Ball ... As with most of the independent variable in ball milling it is best to do some ... Most solids will decrease in volume as ...

How to Calculate Charge Volume in Ball or Rod Mill | Mining . The charge volume of a ball or rod mill is expressed as the percentage of the . The percentage ...

We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media. While the ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

The measurement of the ball charge volume load (or filling degree) is essential to maintain the absorbed power of the mill and consequently the mill production.

Learn more about these metrics Article Views are the COUNTERcompliant sum of full text article downloads since November 2008 (both PDF and HTML) across all ...

The specific rates of breakage of particles in a tumbling ball mill are described by the equation S i = ax α i (Q(z), where Q(z) is the probability function which ...

Optimization of mill performance by using online ball and pulp saimm The complete grindout is required to obtain the accurate ball load measurement or the ...

The charge volume of a ball or rod mill is expressed as the percentage of the volume within the liners filled with balls or rods. When the mill is stationary, ...

Effect of Slurry Density on Load Dynamic and Milling Performances in an Iron Ore Ball Mill Online Estimation of Inmill Slurry Density. Comminution Conference 2012 ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can ... • characteristics of the material charged in the mill (mass, volume, ...

WhatsApp)

WhatsApp)